We Are Stainless Steel Manufacturers In India

Stainless Steel Products – Size Range & Other Particulars | Venus Wires

| Category | Product Types | Size Range | Grades Available | Finishes / Particulars | Applications |

|---|---|---|---|---|---|

| Stainless Steel Wires | Round Wires | 0.10 mm – 15 mm dia | 304, 304L, 316, 316L, 321, 430, etc. | Bright, Matte, Annealed, Soap Coated | Automotive, Medical, Springs, Welding |

| Flat Wires | Thickness: 0.20 mm – 6 mm Width: up to 60 mm |

Austenitic, Duplex, Special Alloys | Polished, Hard Drawn, Soft Annealed | Construction, Fasteners, Consumer Goods | |

| Shaped Wires | Customized Profiles (Square, Hex, Triangular, etc.) |

Austenitic, Duplex, Super Duplex | As per customer specification | Engineering, Electronics, Industrial Tools | |

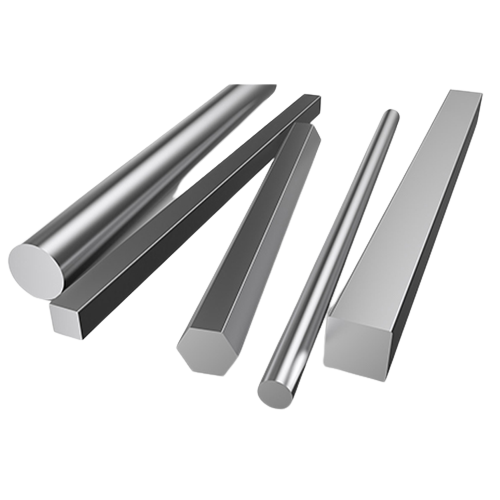

| Stainless Steel Bars & Rods | Round Bars | 3 mm – 200 mm dia | 304, 316, 410, 420, Duplex Grades | Peeled, Polished, Ground | Automotive, Machining, Infrastructure |

| Hex & Square Bars | 6 mm – 60 mm across flats | Standard & Special Grades | Cold Drawn, Bright Finish | Fasteners, Industrial Equipment | |

| Other Particulars | Packaging & Supply | Coils, Spools, Straight Lengths | As per industry norms | Export-grade packing, rust-protected | Global Exports, Bulk Orders |

Our Infrastructure

Infrastructure forms the backbone of any manufacturing business. We have invested significantly in machinery, production technology, and inspection equipment to meet customer and market needs.

News & Events

latest blog posts

Venus Wire Industries Pvt. Ltd.

CORPORATE OFFICE

Mehta Mahal, Opera House,

Mumbai 400004, India.

Click to see map

Plant & Sales Office

Atkargaon, Takai-Adoshi,

Khopoli – 410 203 Maharashtra India.

Click to see map