Our Products

We manufacture Stainless Steel Coarse Wires as well as steel wires in a wide range of sizes, from 0.70 mm to 22 mm (0.028″ - 0.870″). Produced in more than 50 grades, we cover most of the stainless steel grades as well as high nickel and duplex, super duplex grades for hundreds of applications in our manufacturing facilities as stainless steel wire manufacturers in India. These applications utilize bending or forming as the primary process, such as conveyor belting, filtration, and applications using EPQ wires, springs, staples, nails, fasteners, spokes, etc.

Venus also produces Stainless Steel Fine Wires ranging from 0.10 mm to 0.90 mm (0.004″ - 0.035″). The main applications are Braiding, Knitting & Weaving. With a combination of customized chemistry, drawing process and die selection, Venus provides an excellent durability and finish to the material while meeting the mechanical property requirements of the application. Fine wires are generally supplied on plastic spool as per the DIN Specification (DIN 125/160/200/250/355 etc.). Customized packaging options are available on demand.

Venus Wires offers premium quality Stainless Steel Wire Rods for varies applications such as wire drawing, exhaust hangers, lightning conductors etc. We provide customized chemistry to best suit your application. Supplied in the size range of 5.50 mm to 26 mm (0.217” to 1.00”), wire rods are offered in Hot Rolled or Hot Rolled, Annealed and Pickled condition. We also provide the option of soap coating.

Gas Tungsten Arc Welding (GTAW), otherwise referred to as Tungsten Inert Gas (TIG) welding, has versatile applications and produces welds of high standards. Venus produces TIG wires in coil and cut lengths in the size range of 0.80 mm to 6.00 mm (0.030” to 0.236”) in austenitic, duplex, martensitic, ferritic, and precipitation-hardening stainless steel according to the AWS SFA 5.9 standard. Venus offers a variety of packaging options along with customized packaging.

SS welding using Gas Metal Arc Welding (GMAW) or commonly called Metal Inert Gas (MIG) welding is popular in applications where Robotics is used or in Shop floor jobs where continuous weld through machines are preferred. Venus produces high quality mig welding wires and supplied worldwide. These time-tested products, have always demonstrated their superior quality: - be it a stringent welding qualification by the customer or product approval by independent agencies. Produced to AWS SFA 5.9 standards, mig welding wires are supplied either on spool, drum or reel as the application warrants. Customized packaging options are available for distributors.

Venus produces Stainless Steel Core Wires for electrodes manufacturing. We supply to numerous electrode manufacturers around the globe. Our core wires are produced in various grades and supplied in cut lengths or coil form as per our customer’s needs. Customized chemistry for core wires are provided which helps the users with flexibility for flux.

Submerged arc welding is the most preferred mode of welding for Long Straight Seams, Shipbuilding Industries, Oil & Gas Refineries, Fabrication of LPG Cylinders, Bridge Girders & Rotated Pipes or Vessels. Venus produces excellent Sub Arc Weld Wires for the enhanced performance of continuous arc welding. Precision diameter tolerance of our wires makes the job easy for an arc welder. Our SS wires offer superior weld quality and fully comply with the specifications of the American Welding Society (AWS).

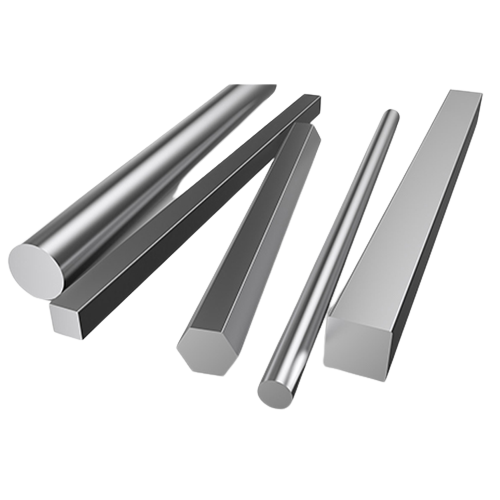

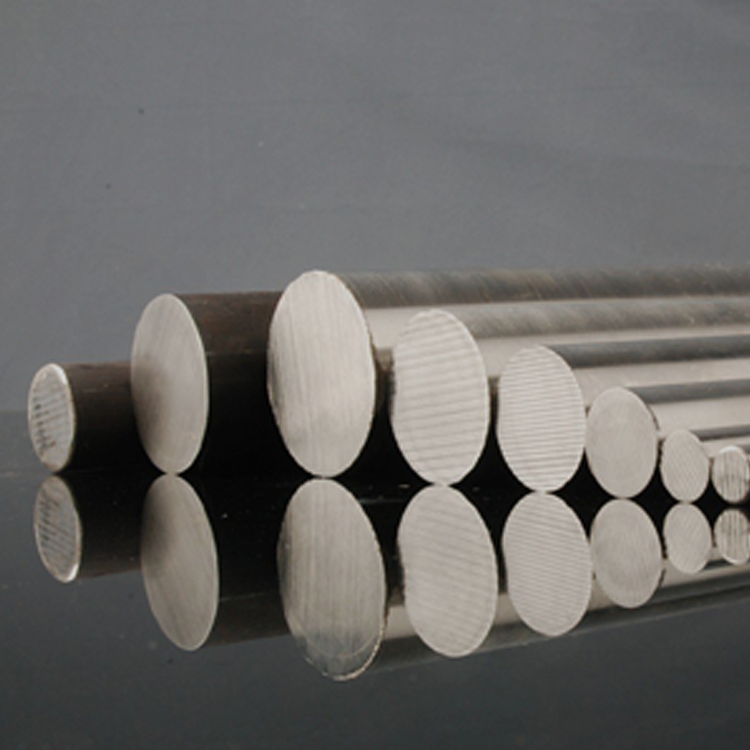

Venus produces stainless steel bars in austenitic, ferritic, martensitic, and precipitation-hardening stainless steel. Produced in the size range of 1.60 mm to 155 mm (1/16” to 6”), Venus caters to several niche markets. With all cold finishing and heat treatment processes in-house, Venus maintains complete control over the final product characteristics. This enables Venus to provide tailored products to its customers in diverse industries. Venus produces its bar products to combinations of ASTM, SAE-AMS, QQS, ASME, NACE, API, MIL EN, DIN, JIS, BS, and GOST specifications, as well as customer-specific requirements and product specifications. Our ability to produce materials with customized chemistry and close diameter tolerances helps us cater to the requirements of the aerospace, automotive, energy sector, power distribution companies, oil & gas, and other industries. Depending on the client's request and standard engineering practices, our round bars are supplied as Cold Drawn, Centerless Ground & Polished.

Venus also produces Hexagon & Square Bars. Our products range from 5mm to 50 mm (3/16” to 2”) with diameter tolerance ASTM A484, ISO h11 and k12. Supplied in cold drawn and polished condition, the products comply to all major industrial standards.

Venus Shaft Quality Bars or VSQ bars are known for its exceptional suitability for shafting. Our VSQ bars are used widely as pump shaft, pneumatic and piston shafts, boats shafts with very little machining due to its close tolerance, finish, precision straightness, no-ovality and internal soundness (100% crack- free) properties. A vast range of ferritic, austenitic, martensitic and duplex stainless steel bars conforming to AISI 303, 304, 304L, 321, 316, 316L, 316Ti, 310, 403, 409, 410, 416, 420, 430, 430F, 430LNB, 431, 630 & 2205 are manufactured at our factory. Our Precision Ground & Mirror Polished VSQ bars find application in the manufacturing assembly lines as Pneumatic Cylinders, Propeller Shafts, Boat Shafts & Pump Shafts.

FITMACH is an improved machinability version of the free machining grades. With tailored chemistry and calcium treatment, the products offer high machinability without compromising corrosion resistance and internal soundness. For high speed screw machining and CNC machining, FITMACH bars are a right choice. FITMACH bars are currently offered in AISI 303(W.Nr 1.4305), AISI 416(W.Nr 1.4005) and AISI 430F (W.Nr. 1.4105/1.4104) grades.

TRU-TUF is Venus’ customized AISI 630 bars. Heat treatment is the KEY for precipitation hardened stainless and our in-house computer controlled furnaces ensures that each bars are heat treated uniformly to the temperature and time as required by the standards for the bars to achieve mechanicals, impact strength and other characteristics. Venus produce TRU-TUF bars in all ageing conditions.

Please send us a query on venuswires@venuswires.com to receive our Soft Magnetic Application Bars brochure.